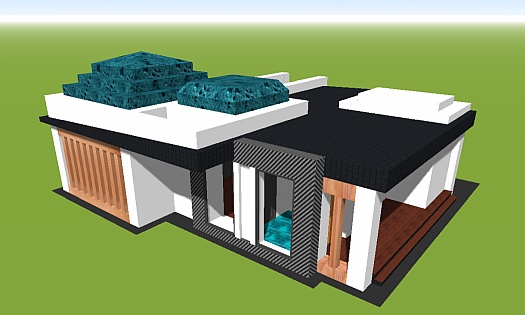

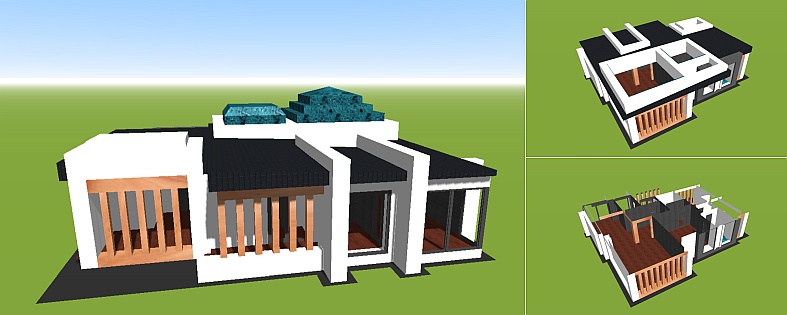

3D house plan of sandwich panel in oriental modern style

To give you an example, here is a 3D model of a house project that has a simple enclosure consisting of building modules with fixed dimensions. It was created using technology that allows you to deliver individual materials so that you can install the walls and window frames yourself. Moreover, if you want to change them even during operation.

Technology for the rapid construction of beautiful houses from sandwich panels

| Technical Specifications | |

| Architecture style: | Oriental Modern |

| House size: | 14x16 м |

| Total living area: | 130 м2 |

| Building height: | single-story |

| Carrier wall material: | sandwich panels |

| Roof type: | combined roof |

| Availability garage: | without garage |

Quickly build a one-story house without an attic from sandwich panels, which does not need to be finished!

Sandwich panels - a technology used in industrial construction. The building is erected quickly, exterior partitions do not require insulation and finishing. From this material was erected and created a warm, cozy one-story house fourteen by sixteen meters.

The single-storey house without an attic was built quickly, and the construction of the house was similar to assembling a construction set. There were steel supports on the floor slab, with a tin roof at the base, lined on the sides with sandwich panels with a natural thermal insulation layer filler. After the windows and doors were inserted, the hallway was transformed into a modern mansion.

Foundation for a house with underfloor heating

The house has no basement and, like many modern houses with radiator heating in the floor, it was built on a foundation slab. The more so because the site on which it was erected had large variations in ground levels. They were leveled out by pouring large amounts of sand on the construction site. A stable foundation was ensured by the connection of the reinforced concrete slab to the foundations. They are located along the perimeter of the building every 5 m, which corresponds to the pitch of the columns that make up the wall structure. The 10 cm thick reinforced concrete slab is the structural basis of the floor of the building.

Steel frame construction with wooden beam

The sandwich panel house is as strong as a production shop, with a frame made of steel profiles and wooden beams. The entire structure is based on metal profiles, and all the columns and cross beams that connect them are made of wooden beams. The beams are inside the building and make up its character, so they have the same cross-section. In order to be able to insert small windows into the outer walls, it was necessary to install steel frames between the columns. They are made of pipes of square section. Large specific full-wall windows with a creative design are made of a strong wooden frame. All the steel elements were powder coated during the production phase.

Warm exterior walls made of sandwich panels BalexTherm

All walls in the house are made of prefabricated elements - sandwich panels BalexTherm, in which two sheets of metal connect the structure and an insulating core of polyurethane foam. For uniformity in the use of finishing materials, steel, trapezoidal sheet on the ceiling and windows made of aluminum profiles were used.

The boards have good thermal insulation (a core thickness of 10 cm provides U = 0.23 W / (m 2 ∙ K)), so they do not require additional insulation or finishing. Therefore it is not necessary to lay plaster or interior and facade cladding. As the metal cladding is exposed on both sides, plus-size panels whose fastenings are not visible from the façade were chosen. The outer cladding is made of 0.6mm thick galvanized steel and is painted. To emphasize the effect, the cladding is made of microprofiled sheet metal. Sandwich panels are mounted vertically and have a length of 4.5 m, taking into account the height of the floor and the length of the wall.

The shape of the exterior design of the house has an invisible roof. In some places, the wall in the house can also be slightly lower and slightly open the roof, made in upside-down roofing technology.

Roof insulation: stone wool slabs

The roof is insulated similarly to industrial buildings. The designers used double density mineral wool boards with a lambda value of 0.038 W/(m ∙ K) that can be installed on a non-ventilated flat roof directly under the roof covering. To achieve the expected thermal resistance, up to 40 cm of insulation (two layers of boards 20 cm thick) was laid. The insulation is separated from the trapezoidal sheet with a vapor barrier. In the second layer the plates are properly shifted to avoid the formation of cold bridges .

Shims of polystyrene foam (EPS 100) are installed on the mineral wool that forms the roof slopes needed for the drainage of rainwater. The surface is profiled towards the inside corner of the house. Along the attic, there is a channel through which rainwater is diverted to a single downspout located in the inner corner of the building. The last layer of roofing is a PVC membrane, which combines the roofing and waterproofing. It is attached through all the layers to the trapezoidal sheet with telescopic fasteners and hot-welded to the joints. This material is mainly used in industrial buildings, where the surface of the roof is huge, and the water drains off it much more slowly than on traditional gable roofs.

To the metal ceiling ventilation ducts fit perfectly into the interior of the rooms.

Internal installations of heating and ventilation systems

Although the house is dominated by a modern minimalist and strict loft style, it is comfortable to use. The heating system throughout the house consists of underfloor heating, distributed over the thermal insulation and powered by a dual-purpose gas stove. In this way it was possible to avoid installing wall heaters. It is more practical because almost all the windows occupy the entire height of the room. Water and sewer pipes are also distributed over the thermal insulation. A layer of concrete C12 / 15 is placed on them, which is also the finishing layer for the floor. After the concrete sets, the floor is resistant to moisture and mechanical damage. Concrete is also a material that is good at absorbing underfloor heating, which is then released into the interior. And irregular-height ceilings allow heat to be trapped at different levels to enhance the ergonomic properties of the project.

The house has mechanical ventilation with heat recovery (recovery system). The ventilation system ducts are not hidden in the ceiling, but remain visible. These ventilation ducts are mainly used in buildings with a much larger cubic volume. They are suspended from the ceiling of profiled sheeting and perfectly complement the character of the interior. Electrical installation is also provided. Scattered throughout the house are black electrical cables and intelligently selected switches and outlets.